Sandwiched Cookies & Fillings

PRODUCT FEATURES:

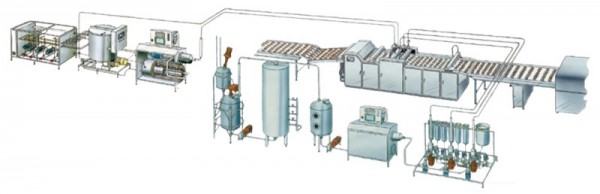

Fully automated high capacity production lines

- Oreo-type sandwich cookies

- Chocopie

- Fresh pie

- Cream & chocolate tartlet

- Cream & jam sandwich

- Mallow & jam sandwich

- Multi-colored cream or marshmallow sandwich

- Multi-coloured chocolate cookies

- Peanut butter cream cookies

SPECIFICATIONS:

Systems available for processing a wide variety of cookie types:

- Sizes ranging from 1 – 5 inches

- Can handle many shapes: round, square, rectangular, etc.

- Many possible fillings: fat creams, pectin jelly, chocolate, marshmallow, peanut butter, caramel, etc.

Filling system including cookie cappers and stencil systems, for use of aerated cream up to 0.7 sg on a stencil sandwich

Filling system capabilities include weighing of ingredients, pre-mixing, aeration & tempering, aligning, indexing, flipping, depositing, and capping

ROTOFLEX MULTI-FILLINGS LINE:

Prepare any combination of two fillings simultaneously in a single compact footprint

- Produce dual fillings for cake bars or sandwiched cookies

- Candy and cereal bars with layered cream, jelly, marshmallow, caramel, etc.

- Co-extruded filling capabilities

- One-shot, center-in-shell, deposited products like: encapsulated marshmallow (marshmallow & jelly); tea cakes (marshmallow & jelly); cake bars (cream & jelly), etc.

PECTIN JELLY SYSTEM:

Fully automatic pH-controlled compact system, also available for cold-set jelly production

Features:

- Automatic start-up

- Tempering of jelly

- Proportioning & tempering of acid, injection of acid

- pH & temperature control of final product

Depositing jelly on biscuits or cookies

• One-shot jelly depositing or co-extrusion with other fillings

• All applications where a quick set of jelly is necessary

• A variety of flavored jelly products from one base mixture using continuous injection of colors and flavors

See our other products

Get In Touch

Location

Naegele Bakery Systems

5661 W 120th Street

Alsip, IL 60803

info@naegele-inc.com